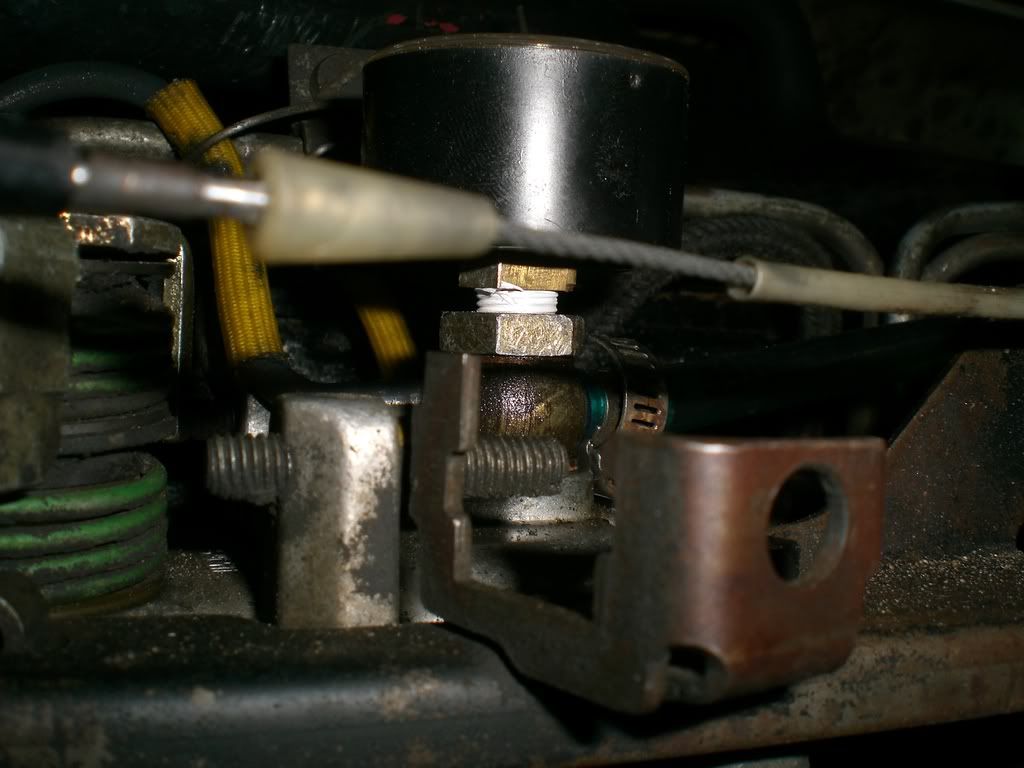

Perhaps what is needed is some way to attach the pressure gauge line to the TOP of the pump? Look back to page 5, (I think,) of this topic; there are pictures and discussion of at least 3 methods.

Steve

Moderator: Fatmobile

I tried it out in the garage: pressure with standard OUT bolt and steady stream of return fuel versus a bolt with no return: pressure was the same. Keep in mind, this is a pump on the bench being rotated with a drill at approximately 1000rpm: not exactly operating conditions in the vehicle, but it seems that if all you want to do is use it temporarily to adjust pressure, it might be alright.Is it alright to not have the out bolt that lets diesel go back to the filter?