Jetta alternator belt tensioner solution

Moderator: Fatmobile

I would think that any flat pulley would work. I looked into belt tensioner pulleys to see if there were any preassembled models that I might be able to bolt to a bracket, but I didn't find anything promising.

I'll be reworking the tensioning on all my belts this weekend to replace the alternator belt and get the slack out of it. The bolt holding the belt-side of the AC compressor worked its way out a few months ago and ground up half of the backside of that belt. :-/ That bolt is impossible to get in, I'm still not sure how it vibrated loose (loctite is my friend, btw).

I'll be reworking the tensioning on all my belts this weekend to replace the alternator belt and get the slack out of it. The bolt holding the belt-side of the AC compressor worked its way out a few months ago and ground up half of the backside of that belt. :-/ That bolt is impossible to get in, I'm still not sure how it vibrated loose (loctite is my friend, btw).

Is this finally the FIX!????

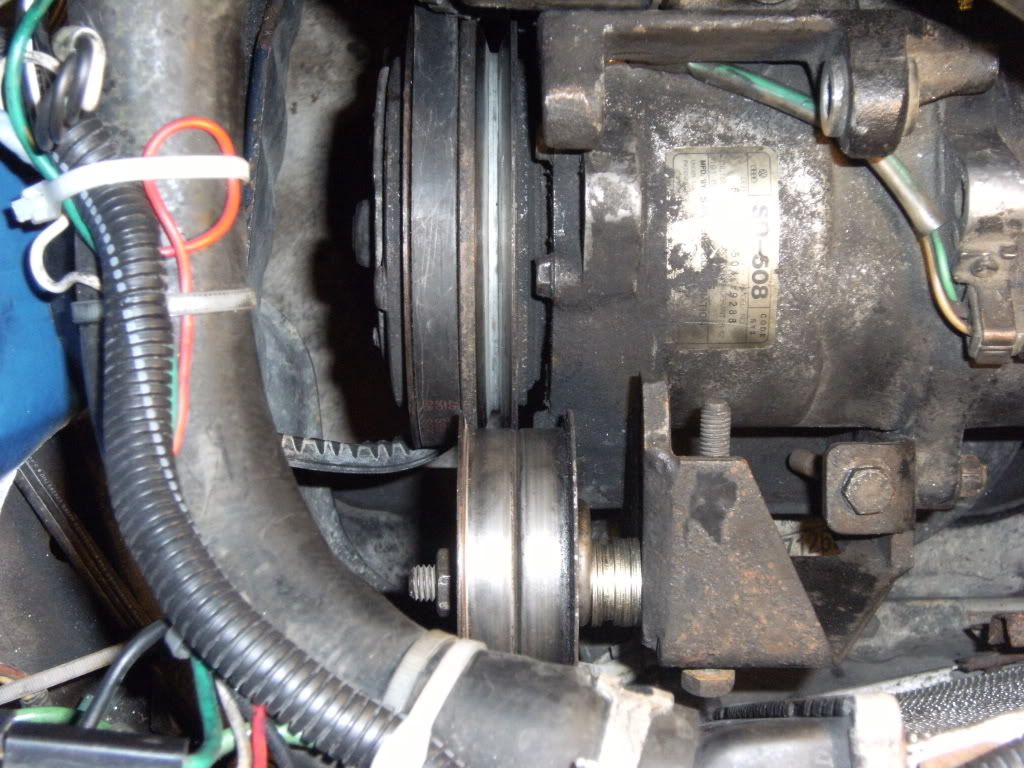

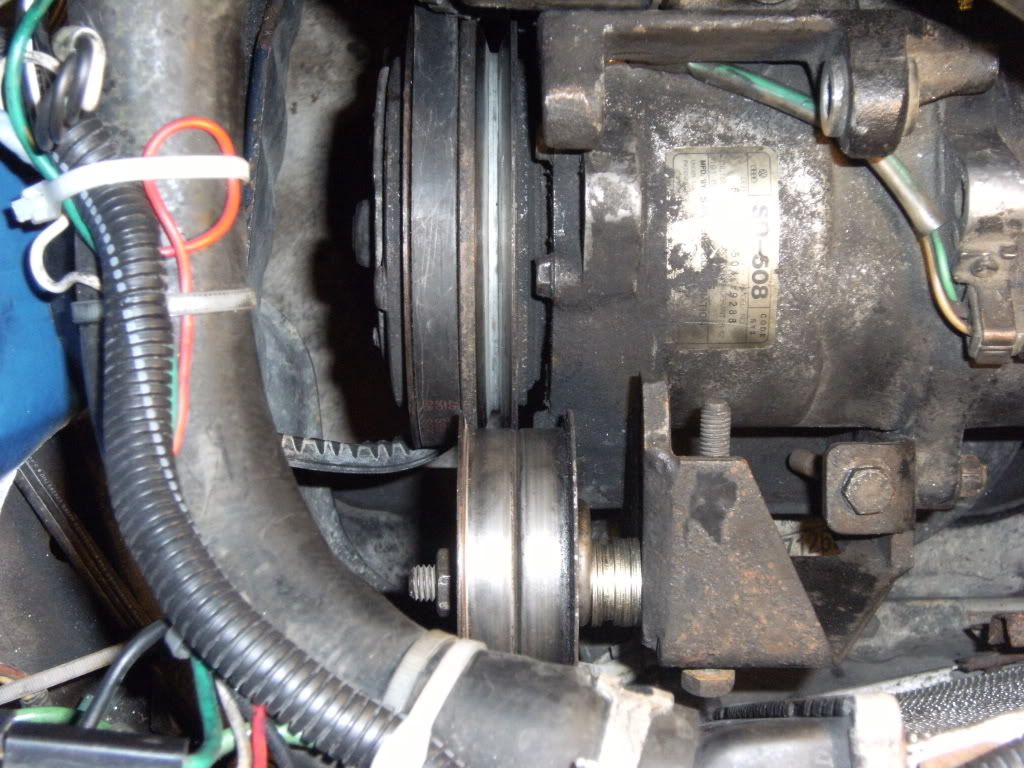

This is my fix. Total cost $12 for a new belt. Here we go.

Go to your favorite parts store and get a Gates 7260 belt. This belt is 1" shorter than the normal belt which is a 7270. The widths are the same.

Remove the stock tensioner (I do recommend keeping it in case you back out of this modification)

Put the 7260 belt in, it will be really tight, but it will go. This should be installed around the alternator and AC pulleys ONLY!

Build up a 13mm set of washers to go over the stock tensioner bolt. (I used a 13mm wrench to measure my stack. Should look like this.

Now get one of those old timing belt tensioners that has been laying around the garage. You will have to grind off the inside shoulder because it will hit the alternator blading. (notice the nice shiny dings on my alternator fan blades)

You will need to play around a bit to get the pulley to sit just where you want, but it will work.

I will post any additional information learned from this modification as I wear it in.

Go to your favorite parts store and get a Gates 7260 belt. This belt is 1" shorter than the normal belt which is a 7270. The widths are the same.

Remove the stock tensioner (I do recommend keeping it in case you back out of this modification)

Put the 7260 belt in, it will be really tight, but it will go. This should be installed around the alternator and AC pulleys ONLY!

Build up a 13mm set of washers to go over the stock tensioner bolt. (I used a 13mm wrench to measure my stack. Should look like this.

Now get one of those old timing belt tensioners that has been laying around the garage. You will have to grind off the inside shoulder because it will hit the alternator blading. (notice the nice shiny dings on my alternator fan blades)

You will need to play around a bit to get the pulley to sit just where you want, but it will work.

I will post any additional information learned from this modification as I wear it in.

-

surfcam

- Turbo Charger

- Posts: 1482

- Joined: Tue Sep 28, 2004 8:43 pm

- Location: Canada Southern Alberta

- Contact:

That looks real good. You should get an "A" for squareness. I use to go through a belt every 6 month until I manage to get a shorter belt on. It's 6 year now since two of us pride it on. I found a slightly shorter Torque belt #14-0764-0. Just by using a shorter belt gets a better wrap on the alternator and can help with the slippage. If the pulleys are warn and the V of the belt doesn't match the pulleys all bet's are off. Your getting a better wrap because the idler is pushing the other way. In your case a longer belt would be better for the wrap but then you would run out of room if you went too long.

Last edited by surfcam on Sat Oct 03, 2009 6:19 pm, edited 1 time in total.

99 TDI Jetta (Z1 engine code)

94 Grand Caravan

89 Dodge Gold Stream B class

http://www.antiquedollhouseofpatterns.ca/

94 Grand Caravan

89 Dodge Gold Stream B class

http://www.antiquedollhouseofpatterns.ca/

Awesome cheap work-around!

This looks great, thanks for sharing it. I'm going to print this out and recommend it to my friend facing the same conundrum!

One question; do you have the VW tension tool for doing the timing belt? I wonder how tight the belt measures. Hopefully it's not too tight!

-Josh

One question; do you have the VW tension tool for doing the timing belt? I wonder how tight the belt measures. Hopefully it's not too tight!

-Josh

-'79 rabbit, getting parted out

-'82 quantum wagon, gutting.

-'84 rehabbed quantum TD sedan, southern rustless beauty for sale

-'82 cherry Westy from AZ

-more all the time; are they breeding?

-'82 quantum wagon, gutting.

-'84 rehabbed quantum TD sedan, southern rustless beauty for sale

-'82 cherry Westy from AZ

-more all the time; are they breeding?

May want to add some thread-locker on that tensioner. It's spinning backwards and could possibly undo the bolt/nut if the tensioner started to drag a bit.

Then again, isn't every nut/bolt on these rattle boxes installed with thread-locker

Then again, isn't every nut/bolt on these rattle boxes installed with thread-locker

Everybody else lists their cars here - but not me.

I have too many to count

I have too many to count

I do have the tensioner tool, I tried to use it but the clearance are too tight. I pushed this pulley into place by hand. I aligned the pulley so that the offset is as far away from other pulleys as possible, but also adjusted the stock pulley tensioner bolt (13mm - the bolt that is impossible to reach and nearly bumps into the radiator) so that I could still shove it close. Hard to explain.

Hope this post helps. I also hope it works. I drove around for about 20 minutes today with the AC on. (my AC belt needs some help, I'm thinking it needs to be shortened up as well). But no squeaks. Seems to work.

Andy

Hope this post helps. I also hope it works. I drove around for about 20 minutes today with the AC on. (my AC belt needs some help, I'm thinking it needs to be shortened up as well). But no squeaks. Seems to work.

Andy

UPDATE$

Unfortunately, my belt solution has failed. Not sure exactly why, but the belt is gone. Pulley is still in place and tight.

Guess I'll go back to the OEM "solution".

Andy

Guess I'll go back to the OEM "solution".

Andy

80 pickup being parted out or rebuilt not sure

82 1.6 pickup

83 GTI (diesel)

86 Jetta

92 Escort (yuck) - Leaving soon

01 TDI Jeta

WVO all the way

82 1.6 pickup

83 GTI (diesel)

86 Jetta

92 Escort (yuck) - Leaving soon

01 TDI Jeta

WVO all the way

-

dieselsnowmobile

- Diesel Freak

- Posts: 193

- Joined: Fri Oct 27, 2006 1:48 pm

- Location: Northwest Indiana

It is amazing with German engineering that they seemed to have missed a basic principle on this, and that is you NEVER EVER put an idler on the tension/pulling side of a belt, it should always be on the untension side. Since VW put it on the tension side, the engine turning the alternator is putting alot of stress on the idler (not to mention that it is sticking an inch out from the frame it is attached to), hence why it keeps losing the belt.

As Vdub-bub great solution did, he put the idler on the untension side and has work flawlessly, and I am sure it will continue to. Good job.

As Vdub-bub great solution did, he put the idler on the untension side and has work flawlessly, and I am sure it will continue to. Good job.

'89 1.6L NA Diesel Jetta (521,000 mi) w/ Rabbit Engine (230,000s mi)

'91 1.6L NA Diesel Jetta (1500 hrs since I have owned it)

'86 2.1L Gas Vanagon 7 passenger (123,000 mi)

YouTube Videos

'91 1.6L NA Diesel Jetta (1500 hrs since I have owned it)

'86 2.1L Gas Vanagon 7 passenger (123,000 mi)

YouTube Videos

-

runitonoil

- Glow Plug

- Posts: 5

- Joined: Sun Oct 29, 2006 10:18 pm

- Location: Ohio

Re: My solution

Do you have the part number or length of that Conti belt? Pulley OD? I want to try out your set up. Very cool. I basically did the same thing with a stock belt and a smaller, homemade idler and bracket. It's better than stock; the belt lasted a year rather than 6 months.91 NA wrote:After almost selling the car because of the hell the alt belt put me through, it threw a NEW belt while a potential buyer was test driving it.

I decided to re-engineer the layout and keep the car.

Here's the solution that I came up with about two years ago.

I've been running the same belt for the last two years (!)

I retensioned it after a year (!!), but because there's so much wrap on the Alternator pulley, (>180 degrees, vs <90 on the stock setup) it can run loose as a goose, and still work great.. even when wet.

I researched marketing this solution, but got scared off by the possibility of being sued by some d!psh!t who forgot to tighten the hold-down nut, and/or thought it was cool to run with the TB cover off, and blows the engine and blames it on the design(er).

To market the kit, I would have become an "automotive parts manufacturer", with all the attendant requirements for manufacturers insurance, etc.

I sourced an aftermarket alternator pulley with a (Ohh Ahh) chrome fake billet cover, and used a flat belt pulley as an idler, tensioning the back side of the belt. As you can see in the pics, it only deflects a few degrees.

It now tensions in the opposite direction, which I apply against the head of the original tensioning bolt, with a piece of 2 X 4. Someone mentioned overtensioning being an issue, but as I said, there is so much wrap on the alt pulley, you don't have to make it tight.

The other design in this thread is brilliant, as it tensions in the same direction, but the amount of back-wrap makes me nervous. It also allows you to use the mechanical advantage of the tensioning bolt to tension the bejeesus out of the belt, which presents the potential for over-tensioning.

I had to machine a sleeve, to sleeve down the ID of the pulley bearing (SAE) to the OD of the bolt (Metric). Also, the tensioner pulley bearing is larger than the stock bearing, and running under less load, so it should last longer than stock (in theory).

I made a second sleeve, and could put a kit together, if someone was interested in running a second prototype... for research purposes only..

I have two years of flawless service, but it may have been a fluke..

I'd have to go back through my notes to see what I used, where I got the parts, and what I'd charge.

Though it doesn't show in these pics, Hagar will endorse my use of a 10 mm Conti belt. Not the "stock" length, though readily available from any foreign parts store. I've been running w/ the SAE Amerikannisher semi-equivalent as a spare, but haven't needed it.

Let me know if there's any interest.

Mark