Page 1 of 2

MK1 200mm Clutch judder in first

Posted: Sun Aug 30, 2015 8:36 am

by sgnimj96

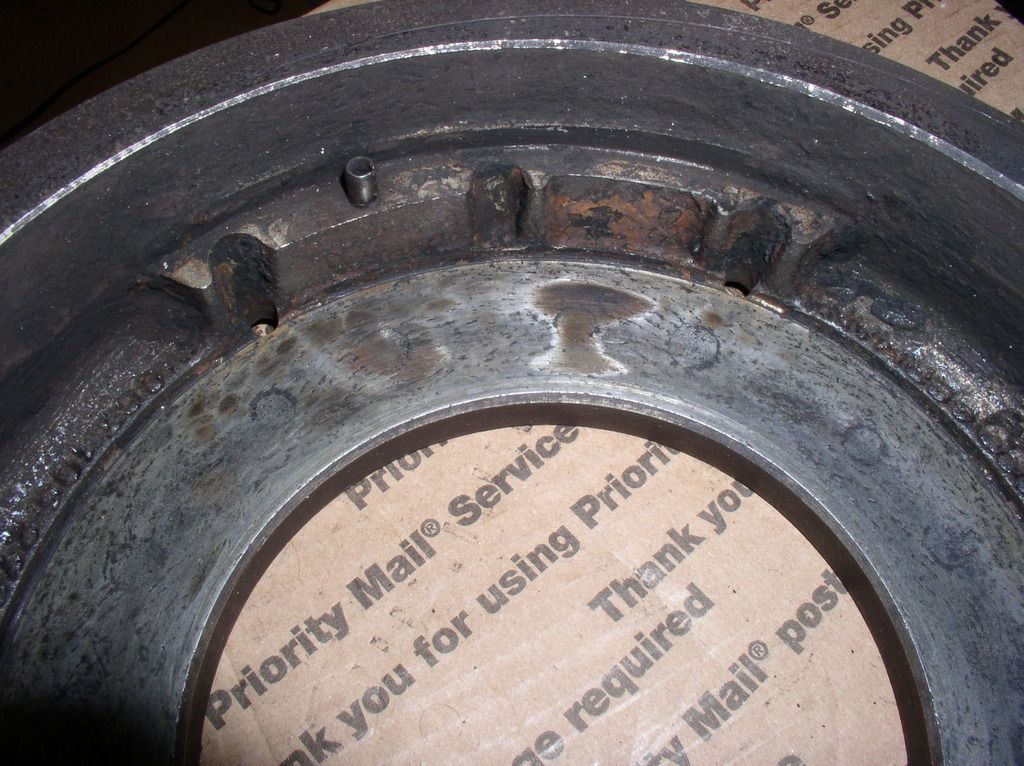

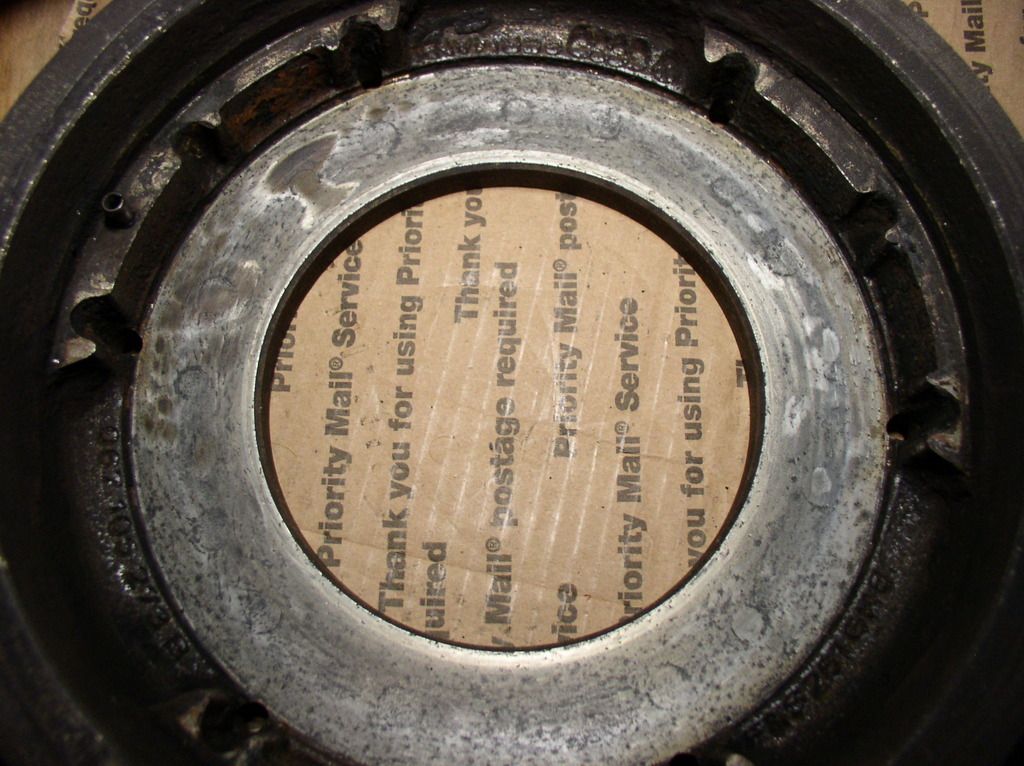

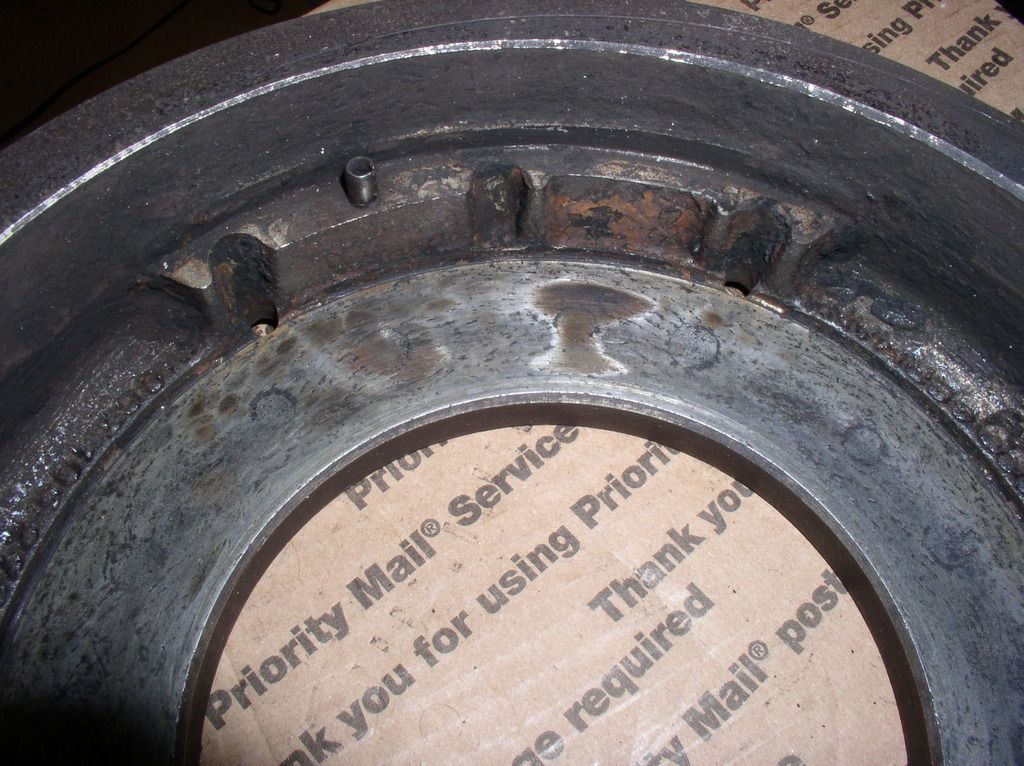

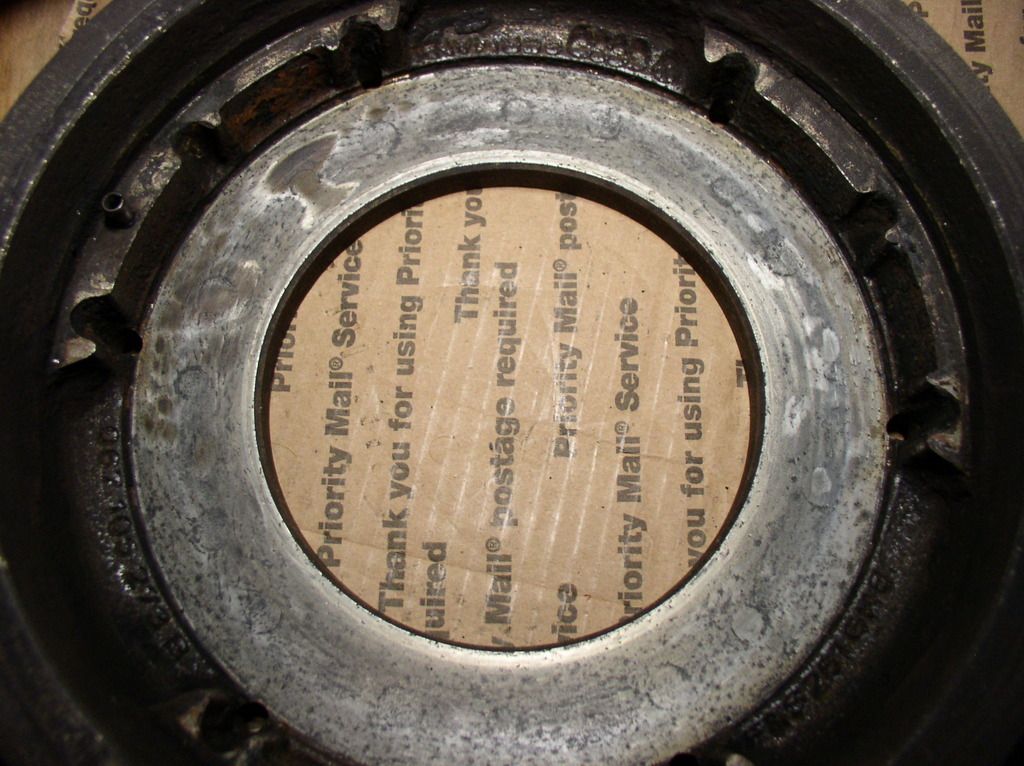

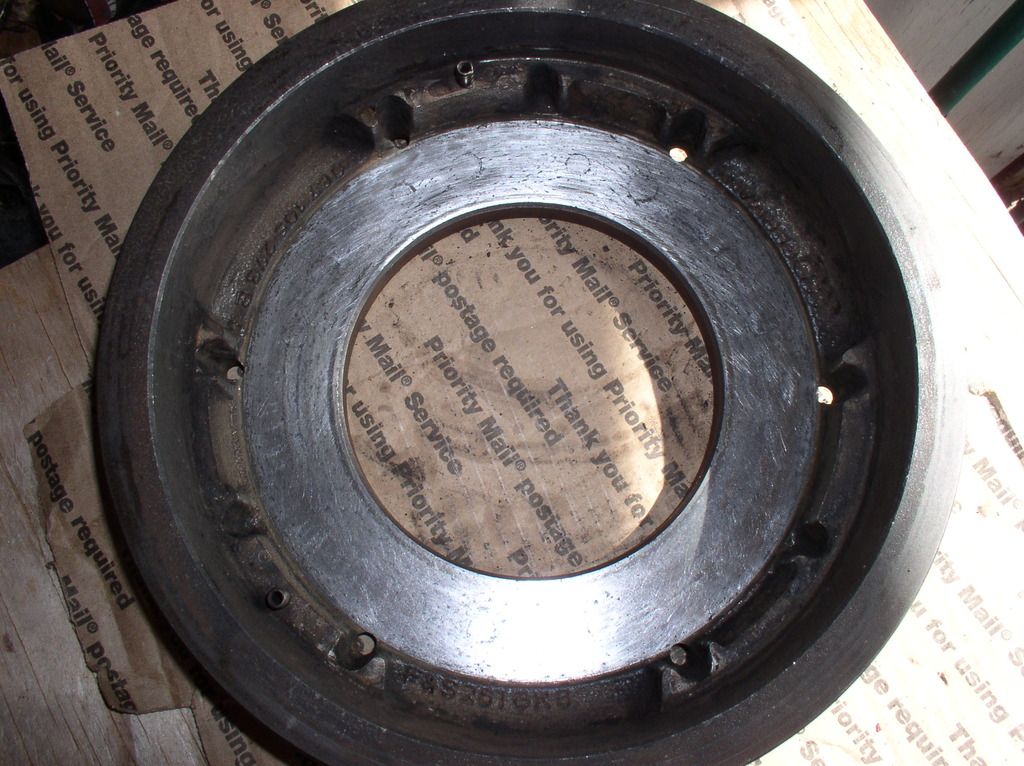

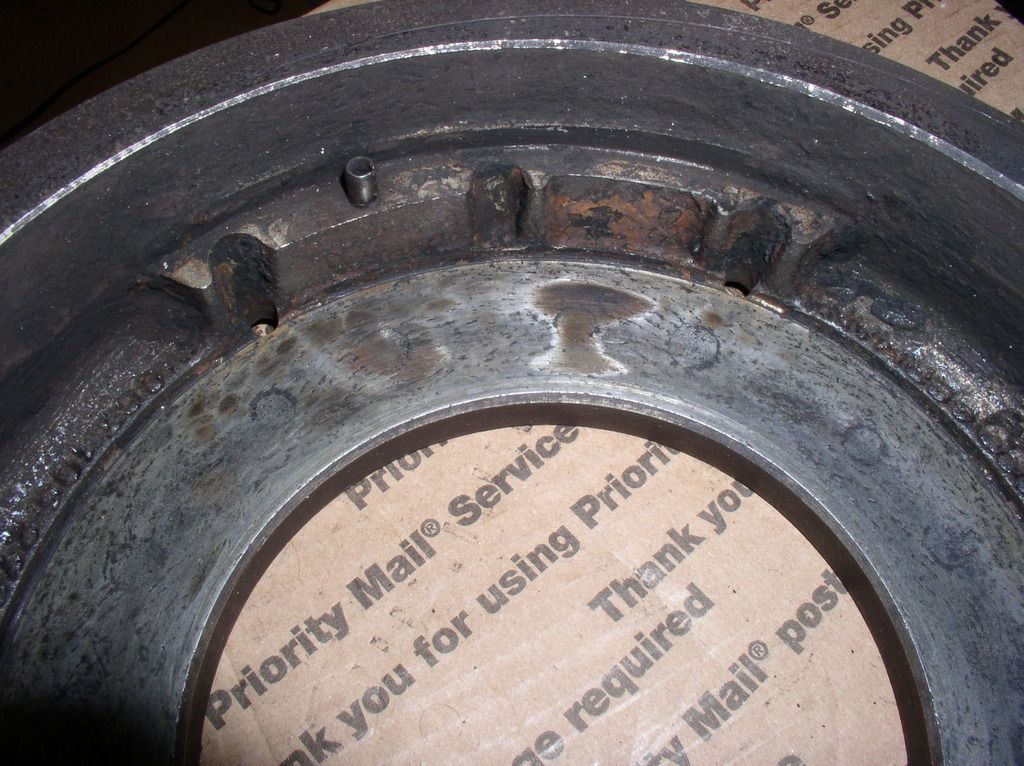

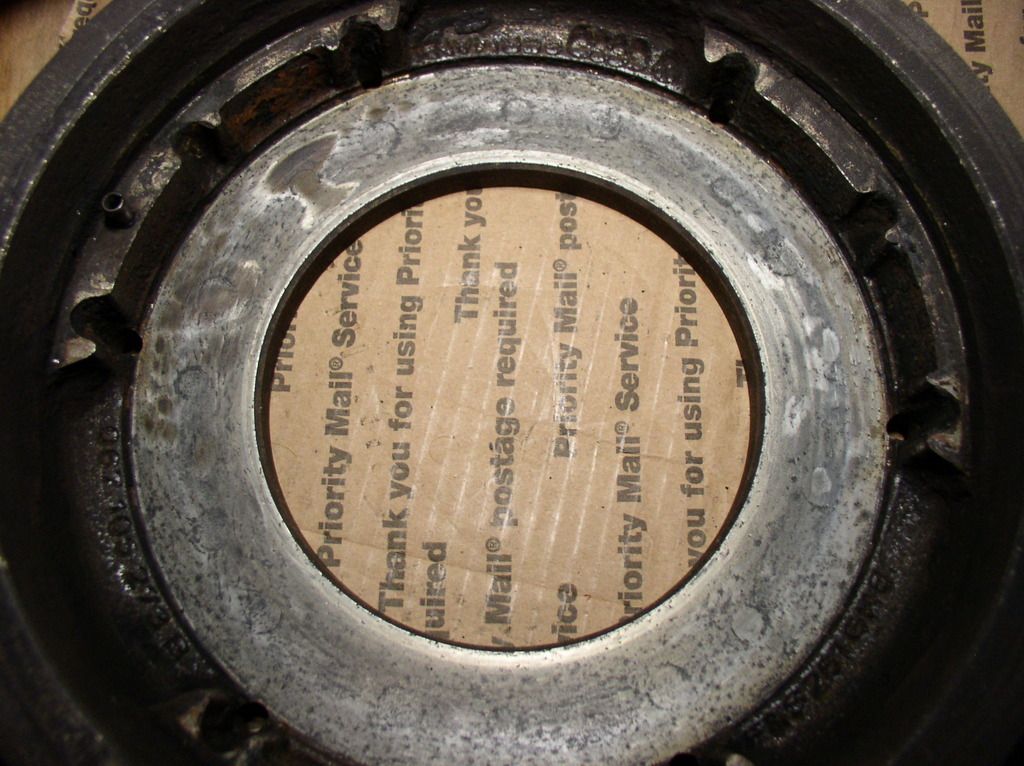

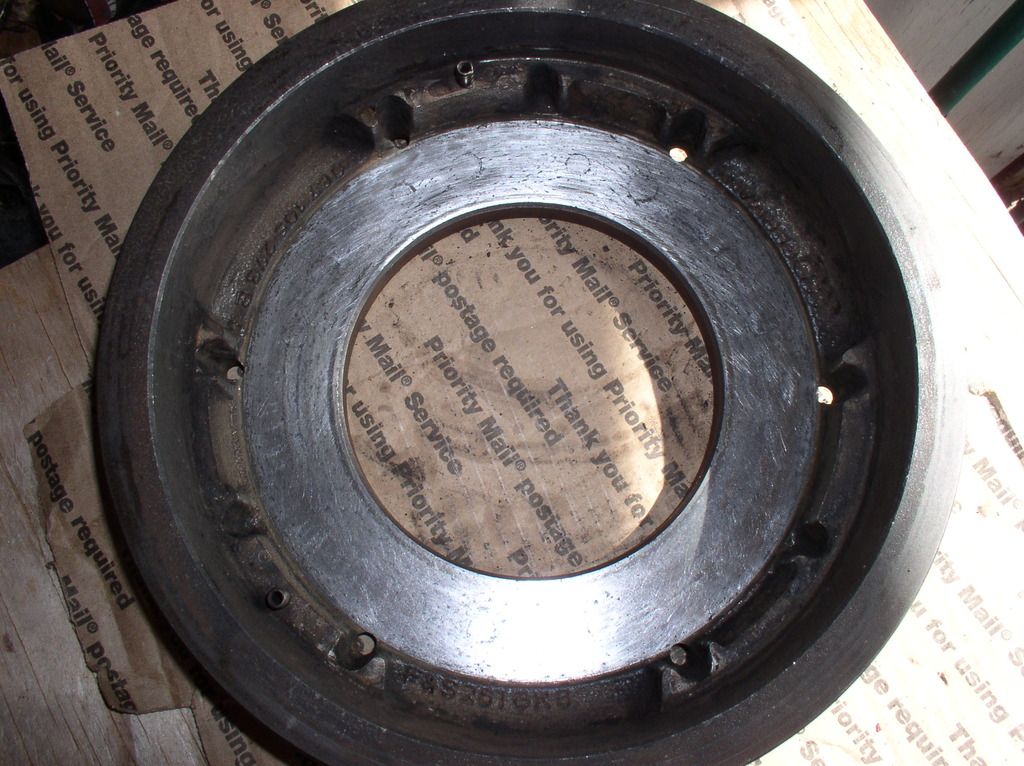

I took the clutch off expecting oil on the clutch. The flywheel looks kinda rough but feels smooth (it's cleaned off)

The clutch lost 2 springs (1 completely destroyed). I think the previous owner was hard on this clutch.

Can I just put a new clutch on, maybe just hand sand the flywheel? I already have a new 200mm clutch kit so I don't really want to spend any extra money upgraded the flywheel.

Re: MK1 200mm Clutch judder in first

Posted: Sun Aug 30, 2015 9:33 am

by 82vdub

I'm not a clutch/flywheel expert, but that flywheel looks like it's going to need to be professionally surfaced to remove the scarred area. That area will likely slip less or more than the rest of the surface area, likely giving a chattering clutch when you reassemble. I'd at least take it to a shop and have them tell you if you can use it or if it needs attention.

Re: MK1 200mm Clutch judder in first

Posted: Sun Aug 30, 2015 10:54 am

by sgnimj96

Thanks

I was hoping the chatter was caused by the broken/missing springs. A european shop here told me that machine-shops are becoming a thing of the past, so it seems like if I could find a place to do it... would get pricey.

Re: MK1 200mm Clutch judder in first

Posted: Sun Aug 30, 2015 9:09 pm

by TylerDurden

Machine shops are still around, but that said... I'm thinking that flywheel is toast.

It looks like the flywheel has hotspots. Those can't really be machined out, the metal in those areas has heat hardened and will not wear like the other areas, even if ground or lathed flat.

It happens to brake rotors too, usually from keeping the pads in contact with hot rotors after a sustained braking event.

Re: MK1 200mm Clutch judder in first

Posted: Mon Aug 31, 2015 7:46 am

by sgnimj96

The only 200mm flywheels is find for sale are used and don't look better.

I've read varied opinions on these flywheels: some people just hand sand, some use a flap disk, some use a grinder (wtf?), some say the original flywheels are better than aftermarket because they're cast, some say the pressure plate must be machined at the same time the flywheel is or the clutch won't work, some say a vw flywheel can't be resurfaced.Wanting to spend less, I'm leaning towards hand sand.

There is one more shop I can call today about machining, but just seems like a roll of the dice.

A new 210 flywheel could be cost effictive

https://www.fcpeuro.com/products/volksw ... 027105270b but I hope TDC would be properly marked; Then I would have to ditch my clutch kit for another one.

Re: MK1 200mm Clutch judder in first

Posted: Tue Sep 01, 2015 9:54 am

by bscutt

I had one machined for $60 but two surfaces must be machined in order to maintain the distance between the clutch disk contact area and the pressure plate mounting surface. Mine had no overheated spots though. You may be able to find a decent used one that can be cleaned up. This is definitely a mill or lathe operation.

Re: MK1 200mm Clutch judder in first

Posted: Tue Sep 01, 2015 3:59 pm

by sgnimj96

Well, since I had nothing to lose I sanded it with some 120 , 240 grit and the surface surprisingly looked better . Maybe It wasn't very clean.

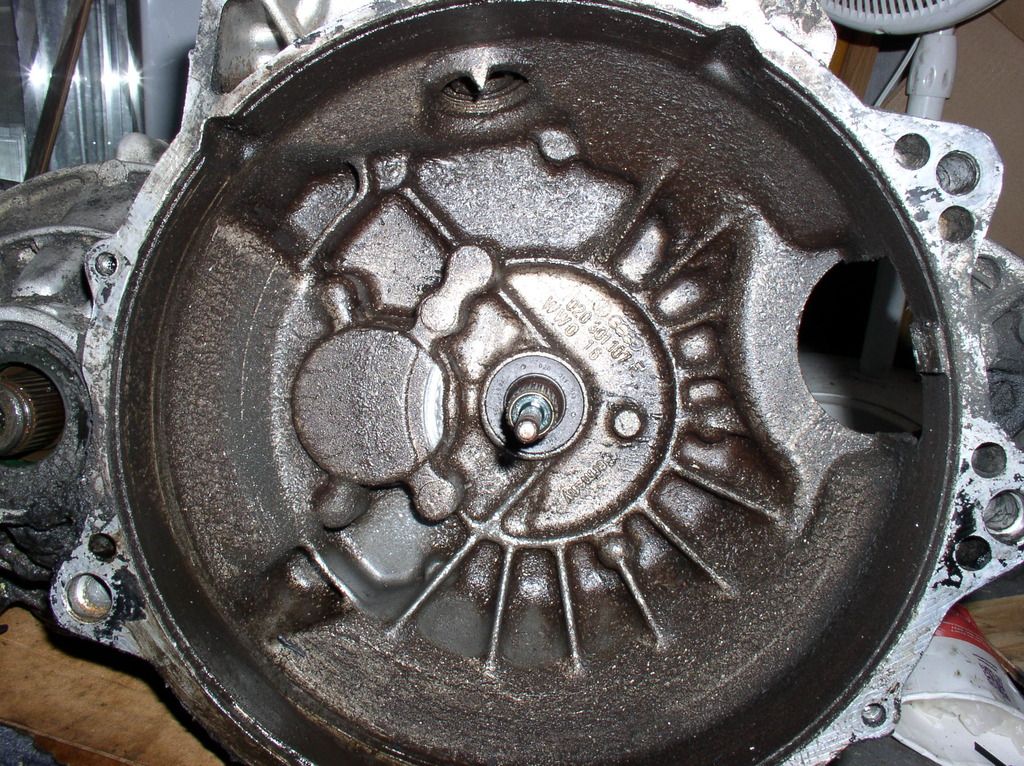

There was clutch/oil mud packed around the edges of the flywheel from oil, rear main seal area looked bad.

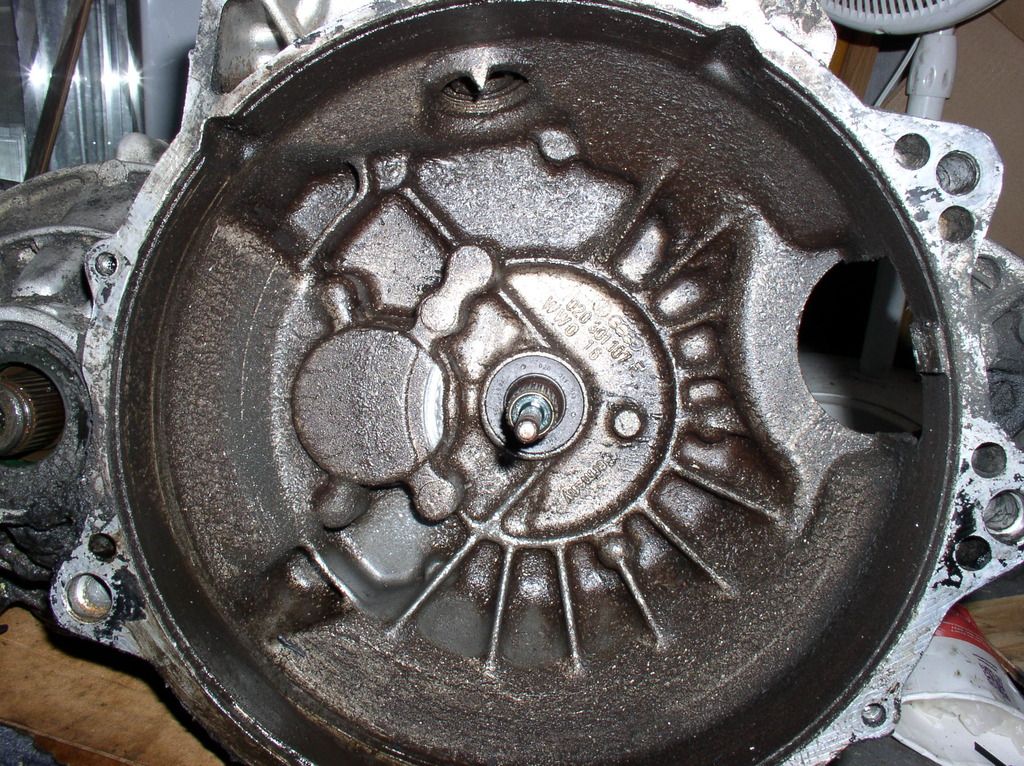

Inside the bell housing was a coating of black oil.

The axle seal on that side (next to the bell housing) was also leaking bad, grease cap had a hole worn in it?. So I'm replacing all those seals, rear main, pushrod; seal and bearing, and booted/reassembled the cv axles on that side (I think the outer cv ring clip was weak).

Re: MK1 200mm Clutch judder in first

Posted: Tue Sep 01, 2015 4:27 pm

by Fatmobile

I'd replace the rear main seal while you are in there. The seal I worry most about is the push rod tube seal in the transaxle.

That one leaks directly onto the clutch when it goes.

Replace that and the guide bushing.

If it was someone else's car I'd have the flywheel machined at Luke's machine, it looks bad when they have to bring it back with a slipping clutch. I'm fortunate to have a local shop that is still setup for it.

If it was mine and money was tight I might just put some sandpaper to it.

What's your location?

Re: MK1 200mm Clutch judder in first

Posted: Tue Sep 01, 2015 5:12 pm

by sgnimj96

Thanks for the comments.

I don't know how good this 020 is, so I don't want to get spendy with it. It's an FN from '82.

I got the rear seal in, made an install helper out of a plastic container. Fit over the crankshaft and the seal slipped right over it, everything coated in clean motor oil of course.

I pushed the seal in a little further than flush (the leaking seal was flush), I hope that's ok

The crankshaft looked fine, and actually the seal looked fine. Not sure why it leaked. Also not sure how an even coat of oil got all over the inside of the bell housing, but it's black like motor oil.

I'm in Florida (town of Melbourne)

Re: MK1 200mm Clutch judder in first

Posted: Wed Sep 02, 2015 3:46 am

by vwtyp133

Metric peanuts!

Good call!

Even with the hand sanding it's likely to have a good deal of shudder. You might want to take your new clutch kit with you to the machine shop when you check on the flywheel. Yeah money's always a factor, but it seems like a disappointment to do all the cleanup, re-sealing & then still have a jerky clutch action that won't get its full service life either.

Anecdotally, before flying out of town for a week, many years ago, I was wife-coerced into loaning my then-new (c.12K miles, just out of warranty

) car to a 'family friend' who toasted the clutch in 2 days! (Turns out he'd never driven a manual trans vehicle, but was too embarrassed to mention it to me.) Short ending: in spite of all my good ol' band-aid tricks... to really get it back to "right", I had to have the flywheel resurfaced, new clutch kit, and even rebuild the hydraulic slave cylinder (still can't understand

how he killed that)! Hence, I take clutch work more seriously than before. YMMV

Best wishes on a speedy & satisfying repair.

Re: MK1 200mm Clutch judder in first

Posted: Mon Nov 30, 2015 9:05 pm

by sgnimj96

UPDATE:

after several thousand miles of driving, including a trip deep into mainland mexico, the clutch with the hand-sanded flywheel is working fine.

Re: MK1 200mm Clutch judder in first

Posted: Wed Dec 02, 2015 9:47 pm

by Fatmobile

Thanks for the update.

It must have been the broken spring.

Re: MK1 200mm Clutch judder in first

Posted: Tue May 24, 2016 8:55 pm

by sgnimj96

10000 miles later, including another rugged trip from Florida to the west coast of mexico, working the clutch hard in mountains and city traffic jams - still going strong.

the Quantum-Man would be proud!!!, nothing but sandpaper and finesse.

Re: MK1 200mm Clutch judder in first

Posted: Thu Dec 09, 2021 11:56 am

by sgnimj96

Update, another 20K+ miles

The hand-sanded flywheel and RockAuto borg warner clutch are still doing their job well.

Shifting is about a smooth as I could hope for after prudent changes of pennz sychromesh.

A clean inj pump with no hang in the rpms also helps for 2nd and 3rd of these primative shift-linkage gear boxes.

I keep a spare clutch cable stashed in the back. One of the cool things of the 020 is, of the few things that can go wrong

by surprise, a clutch cable is easily fixed anywhere if you have a spare.

Re: MK1 200mm Clutch judder in first

Posted: Sat Jul 02, 2022 4:46 pm

by sgnimj96

Still working fine. Just put that flywheel and a new clutch on a rebuilt 1.6d and took it coast to coast across

the badlands of the sierra madre.