Page 1 of 2

Pump rebuild. Now it won't start.

Posted: Thu Jun 07, 2007 12:28 am

by Op-Ivy

I just rebuilt my injection pump and went to start he car tonight. No luck

It appears that the pump isn't producing any suction from the intake line.

The pump has been primed fully with ATF through both the "OUT" and "in" holes. Fuse is ok, timing is ok. Pump spins properly.

Would a hole somewhere else on the pump compromise its abilty to suck?(I think I already know the answer to this one)

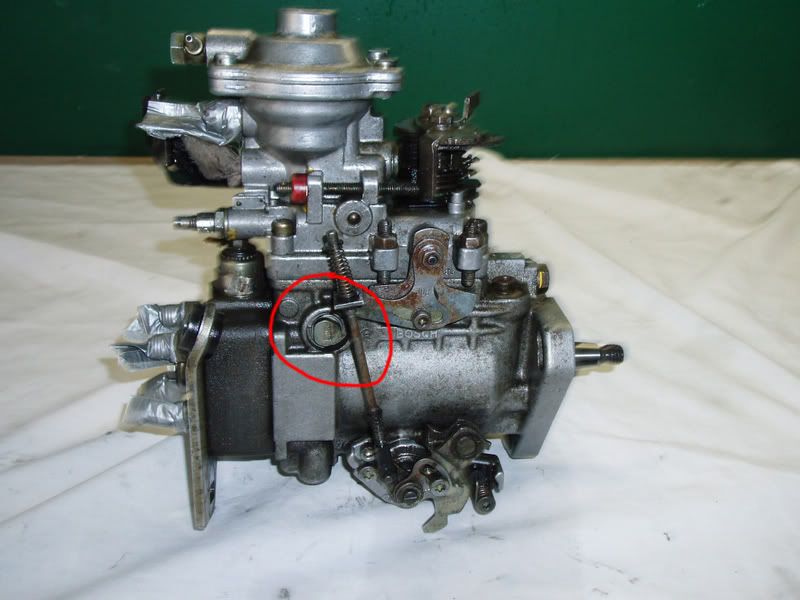

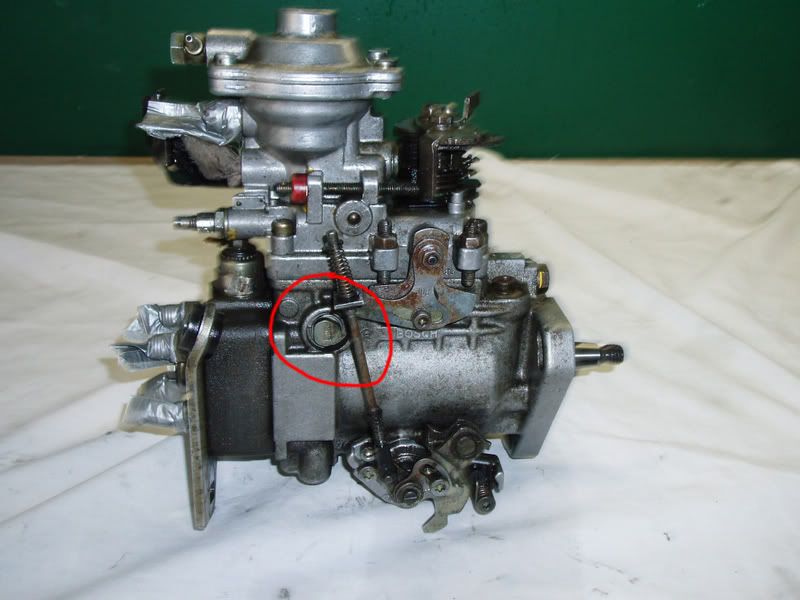

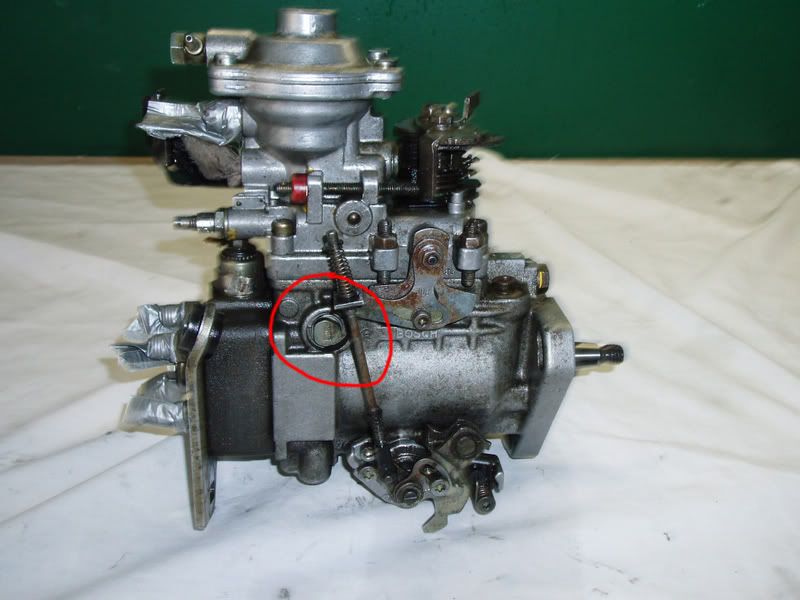

I'm thinking that this "bolt" may be loose, causing the lack of suction. I know the front side one was loose, so this one is very likely to be as well.

Or is it likely to be something else internally? I'm really stumped and disapointed at this point. Any help would be much appreciated!

Thanks, Matt

Posted: Thu Jun 07, 2007 12:49 am

by Vincent Waldon

That's one of the throttle pivot shafts and as it leads into the low pressure side of the pump it could cause a loss of prime. I'd expect it to leak outward as you cranked the pump over (as the pump builds up internal pressure)... strange.

Your rebuild kit should have included two copper sealing washers for these two bolts ? Perhaps tell us a few more details about what your rebuild entailed ?

Vince

Posted: Thu Jun 07, 2007 1:10 am

by libbybapa

The vanes moved freely in the vane pump? The internal pressure regulator is properly installed and in good condition? Timing piston is installed properly?

Andrew

Posted: Thu Jun 07, 2007 1:12 am

by Op-Ivy

I did replace those copper washers on it. I rebuilt pretty much everything on the pump that I could.

-All new seals from the kit.

-Main shaft bushings replaced and hand reamed to fit.

The only thing, that I know of, that was not replaced were the washers that fit on the 4 prongs sticking out that the fuel lines attach to.

No ATF seaped out of the pivot shaft hole and all lines are tight and double checked.

Posted: Thu Jun 07, 2007 1:21 am

by Vincent Waldon

Hmmmm.

Suction is mostly a function of the vane pump... did you disassemble the IP that far ??

If you crack an injector are you getting any delivery (should see something if the pump is full) ?

What are the signs that there's no suction ?

Posted: Thu Jun 07, 2007 1:40 am

by Op-Ivy

libbybapa wrote:The vanes moved freely in the vane pump? The internal pressure regulator is properly installed and in good condition? Timing piston is installed properly?

Andrew

The vanes were working well and in good condition.

I'm not sure what parts the pressure regulator and timing piston are.

Would you be able to identify them in these pictures?

http://s96.photobucket.com/albums/l163/ ... 20Rebuild/

Vincent Waldon wrote:Hmmmm.

Suction is mostly a function of the vane pump... did you disassemble the IP that far ??

If you crack an injector are you getting any delivery (should see something if the pump is full) ?

What are the signs that there's no suction ?

I did disassemble the pump right down to nothing.

The fuel lines are left open at the injectors and are not showing any signs of spitting ATF out.

You can't see the ATF flow down the line(you are able to see the top of the liquid level in the line and it doesn't move)

You can put your finger over the intake line or intake hole and you feel absolutly no pressure

Posted: Thu Jun 07, 2007 2:23 am

by rwest1

Sure you didn't put vane pump in backwards? It flips over for CW or CCW pump rotation. Regards

I P Pumps.

Posted: Thu Jun 07, 2007 1:59 pm

by hagar

Kelowna

BC if you REALLY get stuck --EH ? just phone hagar 604 485 4105

hagar.

prime

Posted: Thu Jun 07, 2007 11:10 pm

by Fatmobile

I prime the pump by hooking a clear piece of 1/4" vinyl tubing to the output and sucking on it until fuel flows through the filter and out the top of the pump.

Just pouring ATF into the pump could have left air pockets in there.

Re: I P Pumps.

Posted: Thu Jun 07, 2007 11:25 pm

by Op-Ivy

hagar wrote:Kelowna

BC if you REALLY get stuck --EH ? just phone hagar 604 485 4105

hagar.

"485" eh? My girlfriend is from Powell river as well! Thanks for the offer! Maybe I'll look you up next time I'm there.

Fatmobile wrote:I prime the pump by hooking a clear piece of 1/4" vinyl tubing to the output and sucking on it until fuel flows through the filter and out the top of the pump.

Just pouring ATF into the pump could have left air pockets in there.

Hmm. Would air pockets cause the pump to not have suction? Does the pump require a liquid to provide the suction, similar to a hose siphoning liquid? If there is air in this hose is it impossible to create the suction?

And by output do you mean the 4 lines that the fuel lines connect to?

Posted: Thu Jun 07, 2007 11:56 pm

by jetta90

Would it be safe to assume that as you crank over the engine and IP. If the plunger inside the pump is moving back and forth like it should be, then there should be fuel coming out of the cracked lines? I'm also assuming the pump would be full of fuel.

Another way of asking the question is - as long as the pump plunger is rotating and moving back and forth there should be fuel being pumped up to the injectors, correct?

injectors

Posted: Fri Jun 08, 2007 12:31 am

by Fatmobile

Before I mess with getting fuel to the injectors, I make sure it is flowing into and through the pump, so I think you are on the right course.

It can flow from the injector lines without the pump being completely full,... like when vacuum is high and fuel lines are full of air. So fuel flowing from the injectors doesn't indicate everything is working correctly.

Since air compresses, priming the pump correctly/ removing all air helps fuel flow.

Like vapor lock in a gasser, the pump doesn't do a good job of pushing something that compresses.

After taking an injection pump apart it's hard to tell what could be wrong.

The vane pump should be attached to the spinning shaft. Not much can go wrong there.

Posted: Sat Jun 09, 2007 3:17 pm

by Op-Ivy

Well, I took the pump apart today. Everything looked in order which confuses me as to what my problem is.

The only thing I saw that might make a difference... Do the chicklets in the Vane go a specific way? That is, left to right not in and out (I know the "cut" side goes inward).

Also, only one of the chicklets was very stiff in there. Would this cause the pump not to suck fuel in?

What creates the high pressure in the pump? Is it the vane pump? That would mean the vane sucks fuel in and makes high pressure as well right?

If so where does the fuel go from there?

Thanks, Matt

Posted: Sat Jun 09, 2007 9:39 pm

by libbybapa

The fuel leaves the vane pump, passes through the internal pressure regulator and into to body of the pump. Although it does get significantly pressurized there, it is not the high pressure portion of the pump. Most of the fuel pumped into the pump body merely runs out the "out" bolt and banjo fitting and is returned to the tank (or fuel filter depending on your vehicle). Some however moves on to the high pressure portion. From the pump body, the fuel enters the fuel distributor and then to the plunger via the fuel cutoff solenoid where it is highly pressurized and sent to the injectors.

Andrew

Posted: Sat Jun 09, 2007 9:45 pm

by libbybapa

I always keep the "chicklets" in their original orientation, but I am quite sure they are symmetrical. Also, with regard to flipping the vane pump over, again, I would keep it in it's original orientation (to prevent extra wear). But, the vane pump is in fact symmetrical and so flipping it over should have no performance effect other than a bit of extra wear as parts need to wear into each other.

I do not know if just one stuck vane would cause it to not pump at all. I think you would need a couple.

Andrew

It appears that the pump isn't producing any suction from the intake line.

It appears that the pump isn't producing any suction from the intake line.